BUILD

AQS offers provides advanced manufacturing techniques that increase the performance and quality of the our customer’s device. We have partnered with top tier companies to support their products and deliver them to market successfully. By offering beginning to end integrated manufacturing solutions, our customers obtain the benefits of supply chain consolidation, consistent manufacturing efficiency and lowered costs. AQS’s global facilities provides us with the competitive advantage by adding a wide-range of manufacturing solutions that make us the premier one stop shop for our customers manufacturing needs.

ONE STOP SOLUTION

From getting involved in early design concept to packaging fully assembled devices that are ready for shipment, our one-stop shop solutions simplify and manage complexity in a the rapid evolving markets. High mix / low volume, quick turn prototyping and NPI services with no limits on quantity provides the much needed flexibility to produce the best product possible. Our operational knowledge across numerous industries permits clientele to reduce working capital in a number of ways. AQS excels at taking conceptual designs and transforming them into tangible quality products. We incorporate turn-key and consigned solutions to maintain convenience for our customers and simplifying the complex process of component sourcing.

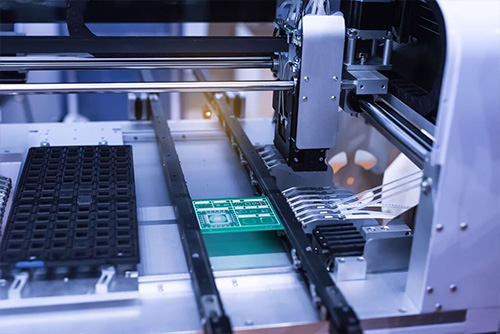

PRINTED CIRCUIT BOARD ASSEMBLY (PCBA)

Assembling Printed Circuit Boards for prototyping & mass production is a specialty for AQS. Our team can support NPI prototypes to mass production. We are flexible in modifying PCB’s to your exact qualification whether it is single or complex multiple layered boards, we have the solution to all PCBA needs. Our state of the art technology and global facilities give us the capabilities to take on any volume of work. Key technical milestones at AQS include:

- POP process

- Able to process 01005, 3 mil micro BGA, AQFN

- Board with size 27×24 mm

- BGA & micro BGA (ball grid array)

- BGA Rework and BGA Reball

- QFP, QFN, & AQFN (advanced quad flat no-leads)

- RoHS/Non-RoHS compliant assembly

- Clean or no clean process

- Mixed technologies (through-hole and SMT)

- 100% Material procurement, 100% consigned material management, or hybrid

- J-STD-001 Class 3

- J-STD-001 with Space Addendum

- IPC-A-610 Class 3

SYSTEM ASSEMBLY

Using AQS’s complete box build and mechanical assembling services will cut time to market while building a complete product ready for market and shelves. We have assembled products for a wide variety of industries sectors such as consumer electronics, medical, industrial, telecommunications, broadcasting, life science, and optics. In addition to our full mechanical assembly services AQS can provide enclosures, electrical testing, burn-in, package design and direct shipping to our end users. We take it upon ourselves to leave all of our customers satisfied and confident in their new high quality products. AQS’s NPI to EMS transition plan will identify and resolve any issues from quality to processing, thus resulting in a lower assembly cost. Our Assembly services include:

- Material procurement

- Consigned material management

- Plastic or metal enclosure

- Complex final assembly

- Encapsulation and conformal coating

- Functional testing and QA

- Environmental stress screening

- Burn-in testing

- Labeling and bar coding

- Kitting

- Documentation inclusion

- Packaging

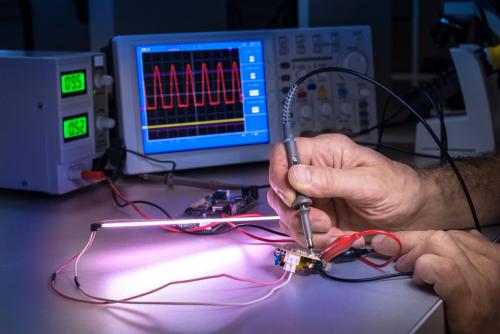

FAILURE ANALYSIS

Learning from mistakes and fixing them are very important in the production process. So we incorporate failure review/analysis of each production lot yielding constant improvement of quality and boosting value. AQS uses a manufacturing execution system to ensure the manufacturing process runs smoothly and reinforce your products quality reducing the risk for failure.